Siemens Teamcenter Foundation

About Siemens Teamcenter Foundation

Siemens Teamcenter Foundation is the most widely used Product Lifecycle Management (PLM) system on the market, providing businesses with a "single source of truth" for managing all product and process-related data. By offering controlled accessibility across key domains—such as systems engineering, product design, quality engineering, manufacturing engineering, supply chain and supplier collaboration—Teamcenter eliminates information silos and enables synchronized and coordinated product information management. Teamcenter Foundation provides a best-practice solution to streamline product development, reduce inefficiencies and foster cross-departmental collaboration.

Teamcenter Active Workspace: A Modern, Web-Based PLM Client

Active Workspace is Teamcenter's web-based client that simplifies PLM access and enhances the user experience anytime, anywhere and on any device. With a modern and intuitive interface, Active Workspace empowers users across disciplines to easily engage with PLM processes and data.

Active Workspace’s advanced search and filtering capabilities display results in logical groupings, making it easy to drill down visually and quickly find what you need. Intelligent charting, filtering by properties, shape and classification, as well as ranked results, enable you to locate information efficiently—even without detailed knowledge of the PLM system’s internal data structure. When critical PLM data is scattered across multiple systems, Active Workspace aggregates it into a single, unified view, eliminating wasted time searching in different locations.

However, finding information is just the first step. It is crucial to understand that information in the right context and make confident, data-driven decisions. Active Workspace delivers role- and task-specific views, proactively surfacing only relevant information to help businesses stay focused and see the bigger picture. Features like Structure Browser and Relationship Browser visually identify critical issues and navigate complex relationships between data elements with ease.

Even users unfamiliar with the intricacies of PLM can easily participate in workflows—reviewing tasks, approving steps, submitting documents and more. With Active Workspace, industrial enterprises can avoid costly mistakes, improve collaboration and make smarter, more informed decisions.

Core PLM Capabilities

- CAD Data Management

- Document Management

- BOM Management

- Process Management

Extended PLM Capabilities

- Requirements Management

- Change Management

- Program & Project Management

- Manufacturing Process Management

- Quality Management

- Supplier Collaboration

Teamcenter Active Workspace Features:

- Context-aware summary views

- Configurable user interface themes

- Dynamic, configurable gateway

- View assignments and participate in workflows

- View change information

- Create and revise items, upload files and edit object properties

- Submit issues, problem reports and change requests

- Full-text search on files and file contents

- Intelligent charting that visually groups search results for easy navigation

- Context-based filters on search results

- Shape search to find geometrically similar parts

- Search and filter data using classification attributes

- Aggregate relevant PLM data stored in external systems

- Save frequently used searches

- Breadcrumb navigation

- Launch information into the appropriate authoring tool in context

- Visualize large and complex 3D product data without additional installations

- Preview requirements and specifications

- Traceability tracking and where-used/referenced views

- Interactive relationship browsing

- Electronic work instructions and 3D mock-up support

Teamcenter Active Workspace Benefits:

- Reduce time to market by enabling faster information retrieval through powerful search and filtering tools, allowing teams to make quicker decisions

- Improve product quality by minimizing costly mistakes and providing real-time access to accurate product data

- Increase efficiency and productivity as the system integrates and aggregates data from multiple sources, streamlining workflows

- Reduce costs by lowering the risk of errors and ensuring that all users, including non-PLM experts, can participate in workflows and approvals

- Enhance compliance with context-aware navigation that delivers relevant insights based on user roles and tasks, ensuring adherence to industry standards

- Improve collaboration and decision-making by visually presenting relationships, structures and dependencies between data, enabling teams to work more effectively

CAD Data Management

Teamcenter offers Computer-Aided Design (CAD) integration that is platform-agnostic, supporting all major CAD systems on the market. By managing your CAD data with Teamcenter, you reduce development cycle times and costs while providing a single source of product data for both design and manufacturing teams. Teamcenter seamlessly integrates PLM capabilities directly within your native CAD tools, optimizing processes from design through manufacturing.

Unlike basic workgroup-level CAD data management, Teamcenter enables close collaboration between design and manufacturing teams by centralizing product data in a single environment. Built for scalability, Teamcenter allows distributed design centers to connect to a unified database and volume server across wide area networks. All CAD-created design information is securely captured, version-controlled and shared with proper access rights—ensuring the right people receive the right information at the right time.

With its multi-CAD support, Teamcenter enables teams to develop components in any leading CAD system and consolidate them into a single multi-CAD product design. It synchronizes product information to ensure all teams work from the latest version while automatically managing both native and neutral CAD formats.

Additionally, Teamcenter’s in-context design and spatial search capabilities help designers quickly retrieve relevant product and process information. For example, a user can perform a detailed search saying, “show me everything connected to the engine, braking system or rear suspension” to retrieve only the necessary multi-CAD data, retaining the full context of the total product.

Supported CAD integrations include:

- Siemens NX

- Solid Edge

- SolidWorks

- CATIA

- Inventor

- AutoCAD

- Creo

- Altium

- OrCAD

- Xpedition

CAD Data Management Features:

- Search, create and edit CAD objects, including drawings, parts and assemblies

- Manage new product revisions and work-in-progress updates

- Create baseline configurations for assemblies to support release or archiving

- Support digital mockup with assembly transformations

- Auto-generate drawing title blocks using Teamcenter attributes

- Support CAD-specific configurations and design tables

- Manage and integrate CAD parts libraries within Teamcenter

- Create and vault DirectModel (JT™ format) files for digital mockup

- Enforce Teamcenter security and data access policies

- Manage design templates and feature libraries

- Define and enforce Item Master naming conventions and object creation standards

CAD Data Management Benefits:

- Integrate CAD files with technical data for a single source of product truth

- Eliminate guesswork and rework by controlling design configurations

- Reduce time spent finding the correct CAD data revisions

- Accelerate time-to-market with faster change and approval processes

- Standardize workflows across data formats, reducing errors and rework

- Enhance collaboration internally and with suppliers and customers

- Reduce CAD license costs by enabling 3D neutral file reviews for non-engineering teams

Document Management

Teamcenter’s document management solution enables the workforce—from CAD users to Microsoft Office users and beyond—to actively participate in the product lifecycle from within their preferred applications. Authors of spreadsheets, documents, presentations, diagrams and projects can easily contribute to the PLM environment, managing supporting documents alongside engineering and manufacturing data. This integration ensures that documents stay aligned with product information and processes, driving productivity and reducing cycle times.

Commonly, documents are created in isolation from product data, leading to misalignment, outdated content and delays. Disconnected processes can result in missed product launches due to incomplete documentation, incorrect labeling or regulatory non-compliance. In some cases, it is not the absence of documents but an overload of unmanaged files that creates confusion about accuracy, status and relevance.

Critical documents—such as product plans, trade studies, customer requirements, regulatory filings and marketing materials—are created by both engineers and non-engineering teams. Teamcenter helps manage these documents within a product development environment, ensuring consistency, compliance and alignment with the latest product data while meeting project deadlines.

Document Management Features:

- Manage bi-directional data exchange between Teamcenter and MS Office documents

- Standardize template usage based on document types

- Embed MS Office-centric Teamcenter interface

- Synchronize MS Outlook tasks with PLM tasks

- Manage access and security by document types, states, user roles, groups and individuals

- Animate and ad hoc workflow

- Change management of versions (releases) and sequences (interim edits)

- Support derived document relationships (where-used)

- Full metadata and full text search

- Save and ad hoc queries

- Easily search and add JT format and other graphic conventions directly into your documentation

- Markup management for simultaneous reviews

- Configure lifecycle states to control release at different document stages

Document Management Benefits:

- Improve product launch success by leveraging a single source of product knowledge that facilitates concurrent engineering and aligned launch activity

- Reduce document confusion by leveraging a single source for secure document authoring, review and access

- Improve accuracy by linking all engineering and document teams

- Improve quality by enabling product and document changes to be planned and verified

Engineering BOM Management

An engineer’s key responsibility is to validate parts and the Engineering Bill of Materials (eBOM) across all configurations before release for downstream use. In today’s fast-paced environment, engineers must efficiently validate parts and BOMs to accelerate product readiness for production and market launch.

Across the organization, there must be a single, reliable source for parts and BOM configurations—ensuring all stakeholders access 100% accurate BOMs with precise part geometry and positioning. Teamcenter’s eBOM management enables this by providing a robust solution for engineers to efficiently author, validate and release multi-domain BOMs. The solution automates BOM alignment with design data and streamlines engineering change processes, acting as the backbone of product structure across the entire lifecycle.

As product complexity grows, many companies struggle with fragmented BOM representations maintained by different departments. These disconnected BOMs are hard to keep in sync, often leading to costly rework, delays and errors due to outdated or incomplete information.

With Teamcenter eBOM, businesses can collaboratively manage a complete part definition aligned with design, spanning the full product lifecycle. By integrating mechanical, electrical, electronic and software domains into a single BOM, Teamcenter helps reduce time-to-market, improve product quality and optimize costs.

The solution supports advanced configuration management—whether by unit effectivity, variant-driven configurations, or product families—allowing release engineers to manage complex product structures without duplicating discrete product variants.

Teamcenter ensures BOM accuracy by combining detailed part geometry and positioning across all configurations. Early eBOM validation allows teams to assess build combinations and quickly understand the impact of changes. Downstream teams can leverage real-time 3D visualizations of valid configurations at any stage of the product lifecycle.

Design and assembly occurrences can be seamlessly aligned to parts and part occurrences via the product BOM. Once alignment is established, each side—design or BOM—can evolve independently, with Teamcenter automation and guided updates maintaining synchronization. Users can also automatically generate portions of the eBOM from the design BOM, or vice versa.

Engineering BOM Management Features:

- Augment and view the master BOM based on role and purpose

- Create a concurrent multiple domain BOM or part authoring at any product level

- Design BOM and eBOM alignment automations and guided BOM updates

- Coordinate changes with automated effectivity management

- Enable a dedicated eBOM user experience

- Use real-time, accurate 3D BOM visualization

- Create multiple flexible BOM views

- Analyze and validate arly builds using an eBOM-driven digital mockup

Engineering BOM Management Benefits

- Collaborate across the product lifecycle using a single source of multiple domain engineering product data

- Coordinate product design, physical product definition and part release authoring and evolution

- Master product complexity with comprehensive variability and change management

Process Management

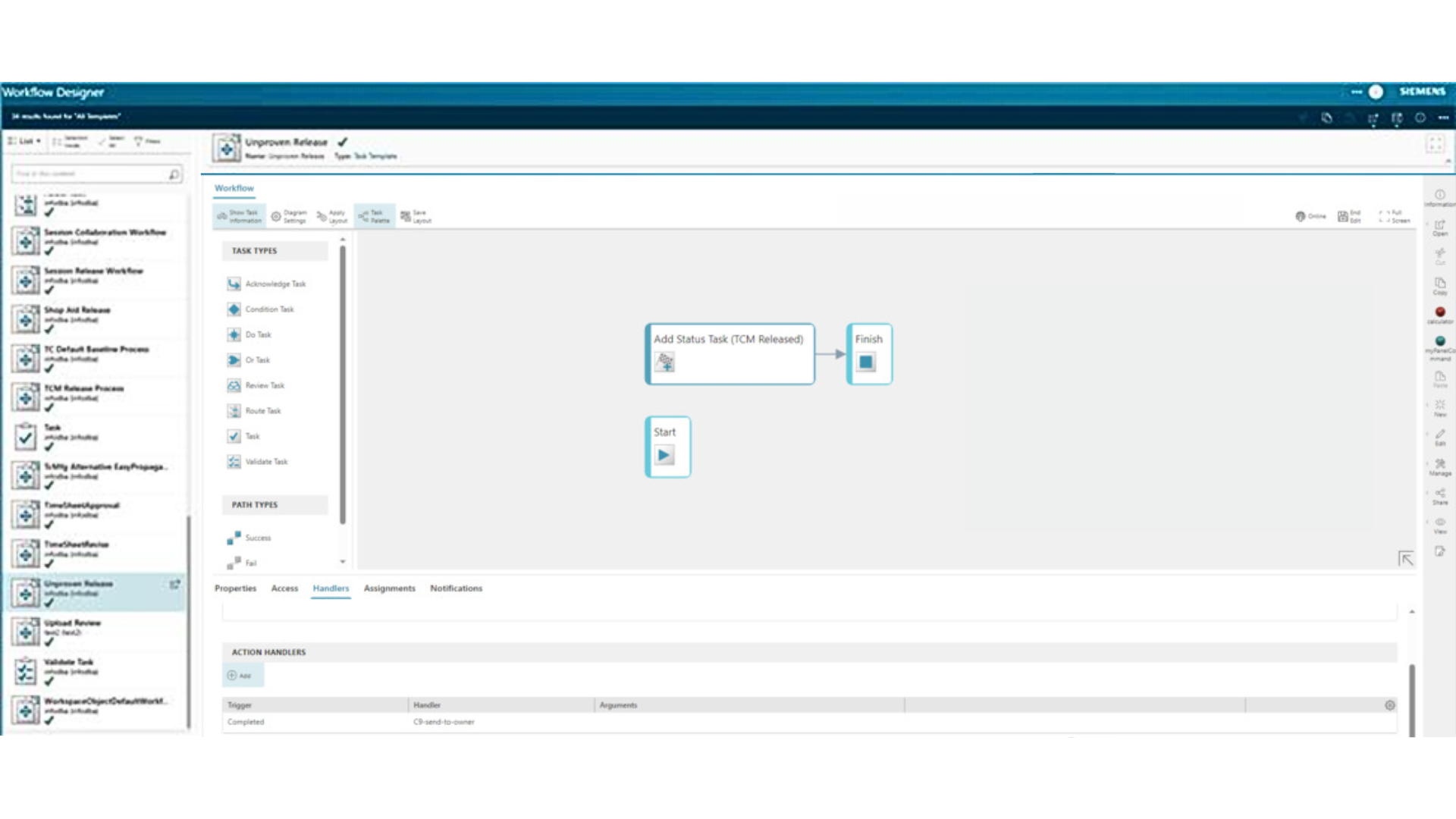

Streamlining review and release processes is critical to meeting design deadlines and accelerating time-to-market. Teamcenter enables businesses to automate workflows using business process modeling, reducing non-value-added engineering time, minimizing errors and cutting costs associated with unmanaged or uncontrolled processes. By automating reviews and release tasks within a single platform, stakeholders can complete assignments quickly and efficiently while working from a unified, up-to-date source of information.

Successful design releases often require multiple reviews to validate requirements, regulatory compliance and customer feedback. Teamcenter simplifies this by providing a single source of truth—integrating CAD files, communications, requirements and other critical data into one system to ensure consistency and accuracy across the organization.

With Teamcenter workflows, companies can manage review and approval processes for any data stored within the system, fostering collaboration across departments such as design engineering, quality engineering, manufacturing and supply chain. This cross-functional alignment helps reduce bottlenecks, avoid miscommunications and ensure faster, higher-quality decision-making.

Teamcenter workflows support a wide range of data and processes, including:

- Item master data

- eBOM, mBOM, sBOM

- Documents and requirements

- Routings and bills of process (BOPs)

- Control plans and non-conformances

- Supplier collaboration and feedback loops

Process Management Features:

- Out-of-the-box workflows

- Customizable workflows

- Customizable workflow triggers

- Historical record of all review processes & electronic signatures

- Real-time Work-in-Process views

Process Management Benefits

- Enhance collaboration and communication

- Improve efficiency and productivity

- Centralize data management

- Reduce the amount of enterprise software systems utilized

- Improve accountability and compliance control

- Decrease quality issues

Target Industrial Sectors

- Automotive

- Aerospace & Defense

- Electronics

- Battery

- Heavy Equipment

- Energy

Engineering’s Expertise

Engineering Industries eXcellence is a trusted Siemens partner with deep expertise in Siemens Teamcenter Foundation. Our specialists help businesses streamline Product Lifecycle Management (PLM) by leveraging Teamcenter’s powerful capabilities for data management, collaboration and digital continuity. With extensive experience in Digital Engineering and enterprise integration, we ensure seamless implementation and optimization of Teamcenter solutions, enabling companies to drive innovation, improve efficiency and achieve their digital transformation goals.

Interested in speaking to one of our experts? Contact us at [email protected].